Petrochemistry | Fuel Combustion | Emission Monitoring

For economic reasons, large container ships mainly use bunker fuel, a waste product from the refinery process. This comparatively cheap fuel has several drawbacks: On the one hand, bunker fuel oil combustion produces exhaust gases that contain sulfur oxides, nitrogen oxides, carbon dioxide, soot particles and particulate matter, polluting the environment to a great extent. On the other hand, particles of the dirty fuel can stick to ship pipes and measuring instruments.

Undiscovered deposits can cause damage leading to considerable repair costs or even engine failure. Significantly stricter legal limits for the emission of sulfur oxides from ships have been in force since 2020. Ship operators are instructed to measure and adhere to these limit values for sulfur oxide.

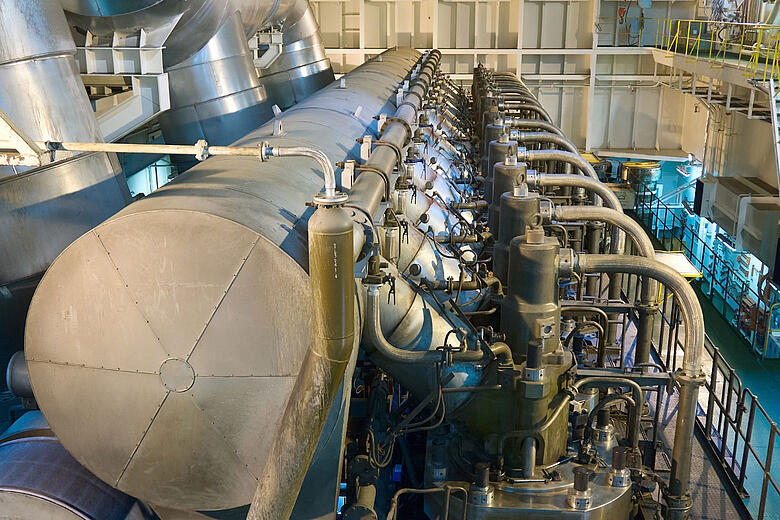

Engine room of a vessel

The composition of the heavy fuel oil on board can vary from tank to tank and is not necessarily homogeneous even within a tank. It is also possible that the distribution of the constituents of the heavy oil changes while it is in the tank. The engine control and the amount of pollutants depend on the composition of the oil. The sulfur content in the liquid heavy fuel oil is directly related to the sulfur oxide that forms during combustion. To protect the environment, health and climate, its legally regulated limits must not be exceeded.Reliable measurement of the individual components of the liquid fuel is significantly hampered by the high temperatures and pressures that prevail in the pipes. The integrated measurement technology must also comply to the regulations relating to use in explosive environments.

Despite these harsh process conditions, the instruments must measure reliably and precisely and at the same time be designed in a way that they have a repellent effect on particles that may adhere. It is also important that the integration into the process environment is as simple as possible to keep costs low.

For the reliable control of sulfur oxide emission and to allow for immediate intervention if necessary, precise measurement of the components of the bunker fuel in real time is essential. The decisive factor is the sulfur content of the fuel that is fed to the engine. For the best possible control of the engine and to ensure that the legal limit values are adhered to, the sulfur content must be known at all times. During the supply of the heavy fuel oil, first heated to improve pumpability, to the internal combustion engine, the individual components of the liquid oil are measured.

A more detailed description on how this application was realized using online measurement technology can be found in our detailed application report, which you can download from the info column at the top of the page.