Chemistry/Pharma/Food | Multi-Stage Production Processes | Polymerization

Whether it is medicine, food, household appliances or clothing - behind the final product frequently stands a complex, multi-stage and strictly regulated manufacturing processes. In large industrial production plants, raw materials are processed in several steps to produce a wide variety of end products. This is the case, for example, in the production of plastic in its various forms. Due to increasing requirements in terms of efficiency, output and product quality, several measuring points at different reactors or production lines often have to be continuously monitored during the manufacturing process. Precise and reliable measurement data form the basis for optimum process control.

Process Control

Industrial companies with a multi-stage manufacturing process must closely monitor many spatially distant measuring points while keeping the costs per measuring point as low as possible.

For reliable analysis of liquid components in real time, the use of online analysis technology has proven its worth. With the aid of optical components, such as a process probe or measurement cell, precise measurement data is transmitted to a spectrometer via fiber optics and evaluated.

The investment costs for these measurement systems can be very high, especially through the acquisition of several spectrometers. Furthermore, the calibration, operation, and maintenance of multiple instruments means significantly more work.

Complex production processes including several process steps can often be found in manufacturing companies in the chemical, pharmaceutical and food industry. In the process of producing various plastics for everyday use, for example polymerization, chemical reactions take place at short intervals and must be closely monitored.

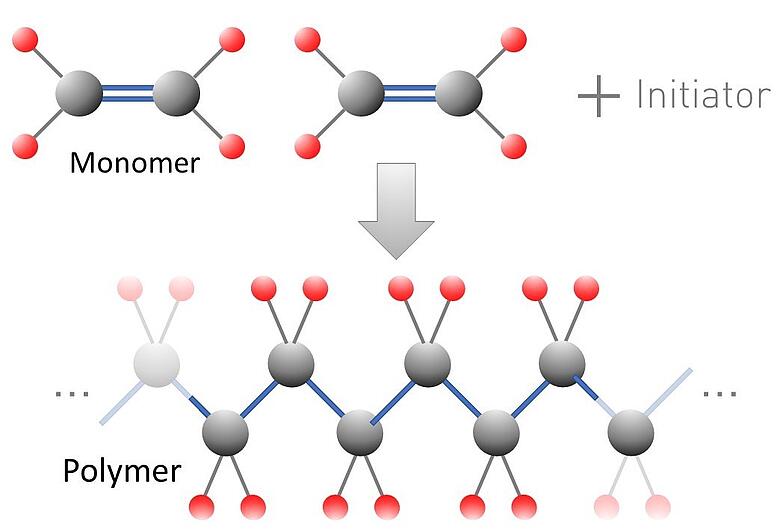

Polymerization describes the process by which small units (monomers) are chained together through repeated reaction steps to form polymers - the synthetically produced form of plastic.

Initiators, fillers and other components added to the monomers during polymerization, have an influence on the subsequent properties of the plastic, such as pliability.

Example of a polymerisation

Through rapid recognition of the reaction progress, a polymerization can be optimally controlled

For optimum process control and high efficiency, it is particularly important to monitor the reaction process in real time using online measurement technology to determine how fast the reaction progresses and when the polymerization of a batch is completed. This can often be best achieved by means of NIR spectroscopy.

NIR spectroscopic measurement methods can also help to monitor the process during the further processing of polymers into numerous finished products, such as synthetic fibers. Other measurement points can involve solvent recovery or addition of additives to give plastics specific properties.

It is therefore not unusual to find multiple measuring points in a manufacturing process, each of them equipped with its own spectrometer. Consequently, the costs per measuring point can take on larger proportions.

A more detailed description on how this application was realized using online measurement technology can be found in our detailed application report, which you can download from the info column at the top of the page.