Technical test centers (TP) and certified car workshops in Germany perform almost 24 million emission tests on cars, commercial vehicles and motorcycles every year. Growing environmental awareness and the introduction of special emission tests in 1985 and 1993 led to a continous further development of regulations.

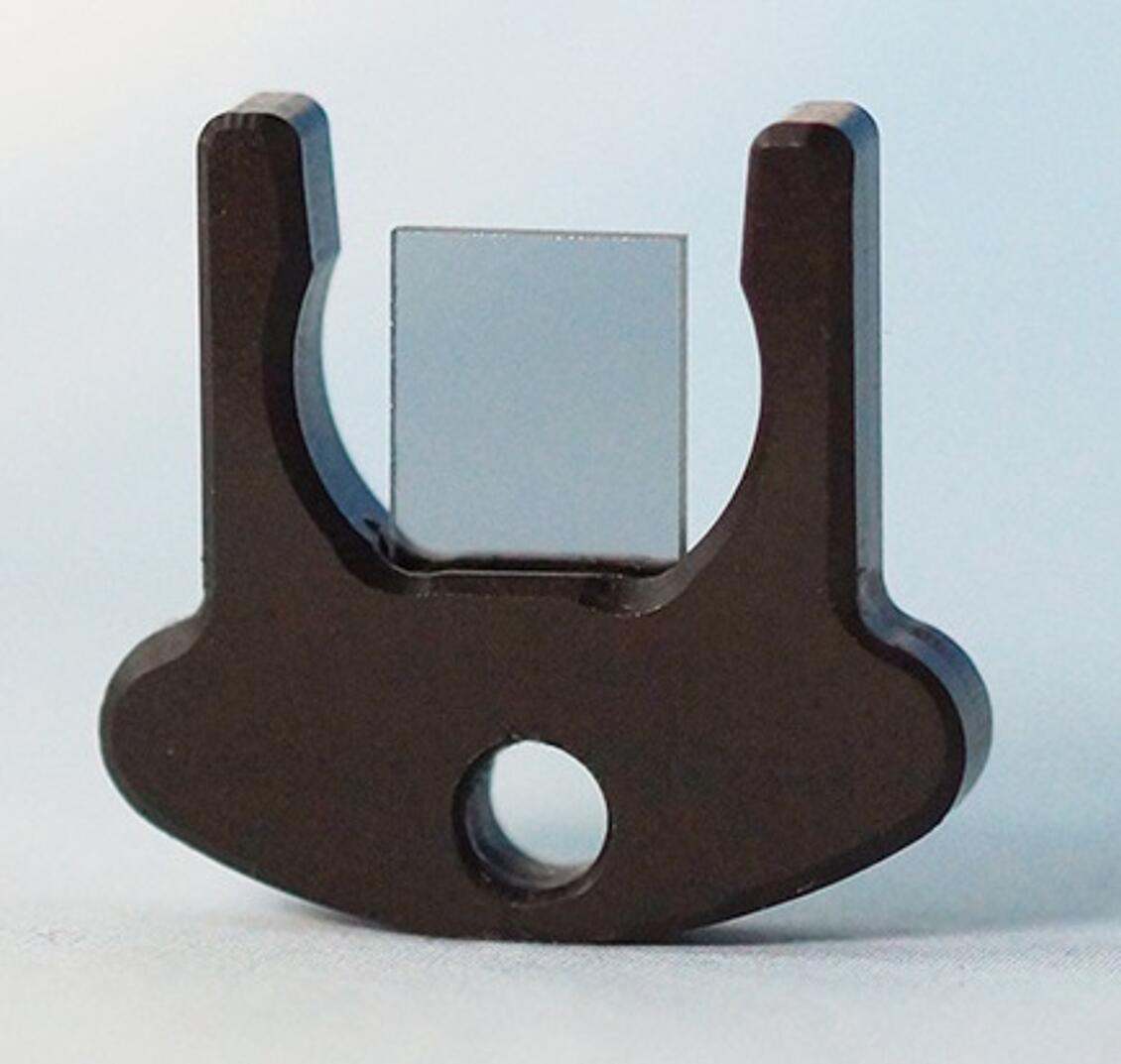

Vehicle emissions have been in the spotlight for some time, not least because of the diesel emission scandal and constantly increasing demands on the exhaust gas behavior. Emission tests are performed directly on the exhaust tailpipe with special devices, such as the emission testing device produced by Hella Gutmann. A reliable exhaust testing device that provides accurate measurement results belongs to the basic equipment of any good car workshop and test center.

New regulations have recently been introduced to guarantee measuring accuracy and reliability of these devices.