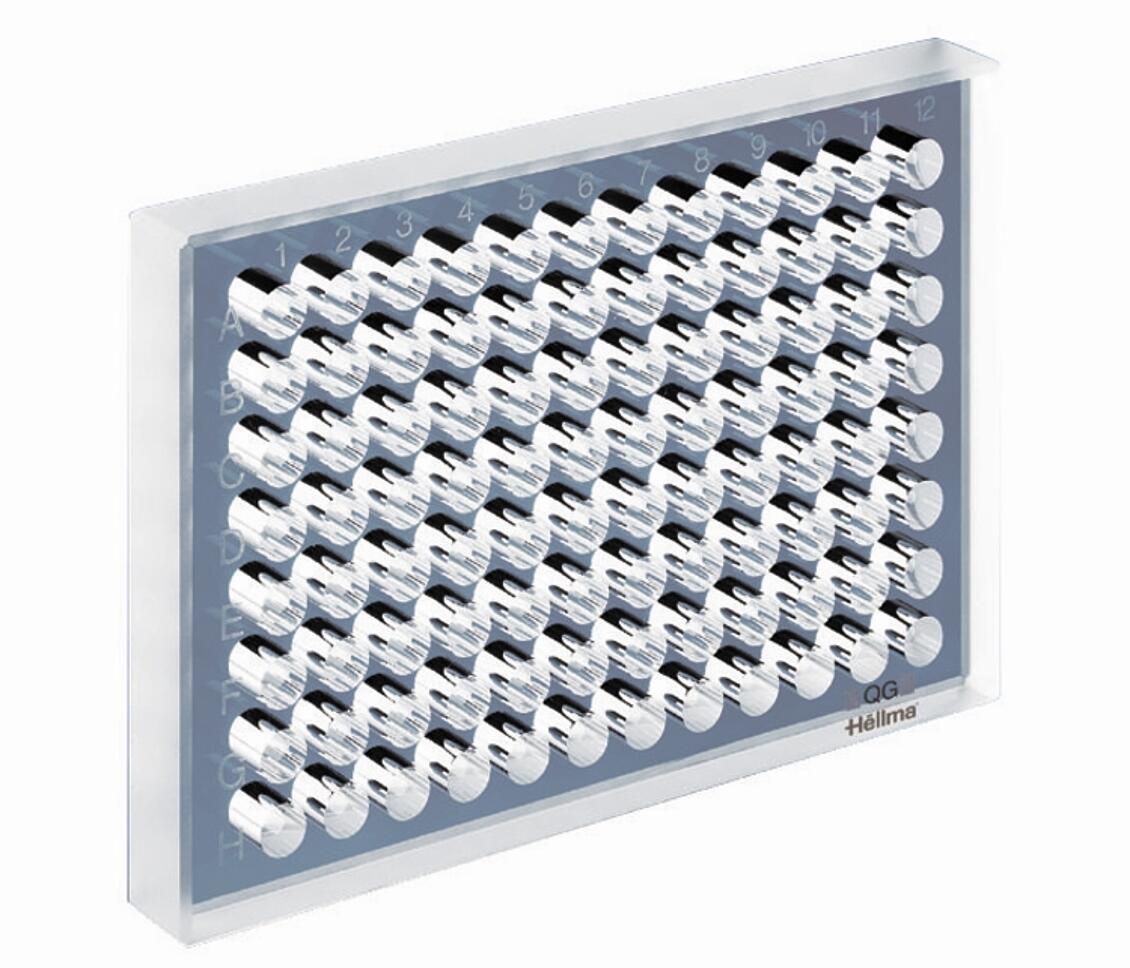

Microplates are being used increasingly in areas such as clinical chemistry and pharmaceutical research. However, the common plastic microplates are not suitable for many applications. If chemical resistance, UV transmission, microscopic observation or thermal stability are required, it is better to use quartz microplates. Hellma’s quartz are manufactured to the same dimensions as the plastic plates.

The upper part of the microplate is attached directly to the synthetic quartz base using the process of direct fusion rather than glue or sinter glass. The result of this joining process is an evenness of the well base that is less than the wavelength of light. The connection has the same resistance against extreme temperatures and aggressive chemicals as the monolithic quartz body. Furthermore, this guarantees that each well is completely watertight.

| Article-No. | Description | Base in mm | outside dimensions in mm HxWxD |

| Standard Microplate | |||

| 730-009-44 | Microplate made of synthetic quartz glass (QG) with 96 wells | 2 | 14.5 x 127 x 85.5 |